Blog

Five lighting solutions

Fully lighting a warehouse at all times is one of the least-efficient ways of operating the facility - and the higher costs over time make it a financially poor decision in just about every single case. These five lighting solutions for energy efficient warehouse operations will improve your premises without impacting on workers' ability to do their job.

Zoning

Most warehouses have already begun the move towards sensibly zoning the facility by placing the most-picked items in close proximity to their final destination while infrequently-chosen items are allowed to languish in the rear.

This philosophy encourages zoned lighting, where low-hanging arrays can be installed to reduce the expense needed for lighting a given area.

Controls

Warehouses are understandably hesitant to implement manual controls for lighting aisles - the few seconds it takes to walk over and flick the switch can add up to a lot of lost picking time over the course of a year. However, automatic controls (such as occupancy sensors) have developed to the point where it's now practical to use them in a warehouse setting. People within the warehouse can simply move right to their destination without worrying about the lighting - though it's important for them to be able to see any hazards that may be in the way.

It's not yet practical to have separate controls for an entire aisle of products, but as technology advances, this will be worth looking into - why light the whole aisle when an employee only needs to move halfway?

Dimming Systems

Warehouses don't need to limit themselves to on/off switches. Dimming lights are also an option, particularly in any area that receives a significant amount of natural lighting. Sensors keyed to this can work in tandem with occupancy sensors to limit the lighting of the facility and ultimately create a truly efficient warehouse.

Dimming systems may also be worth using in areas well away from windows and doors if those areas still receive a lot of natural lighting. For example, windows that face the sun may offer enormous opportunities for natural lighting throughout the day, requiring only a minimum investment in lighting outside of the morning and evening hours.

LED Arrays

The dropping prices of LED arrays are making them an increasingly practical choice for warehouses that rely on higher arrays for providing adequate illumination. This isn't a minor consideration for any facility that's looking at replacing its current arrays - though it's also important to keep in mind that most of the savings from LEDs come over time, and they still tend to be more expensive when first purchased.

Over the next seven years, LEDs are expected to make up about half of the overall market for lamps, and further developments may speed this along.

LEDs are also more practical at lower levels, particularly for high-traffic areas where lights will need to be on almost constantly. The steady illumination and high efficiency are worth enough that many warehouses (and similar large, open areas) are at least seriously considering the change.

Alternative Solutions

High bays are not the only lighting solution that many warehouses should focus on. In many cases, alternative options like waist-level lamps along walkways can provide adequate illumination without the cost or waste of a higher array. This is something that can only be determined on a case by case basis - warehouses have many different designs, and alternative solutions require creativity as much as anything else.

The keys to keep in mind are the available technologies and the actual cost of the solution. Revisiting the lighting design of the warehouse on a regular basis can help ensure that it's always functioning in a sensible, affordable, and energy-efficient way.

AutoStore Logistic.

Hatteland Logistics located in Nedre Vats, south of norway - has developed this amazing logistic system. the photage in this video is shot at Komplett.no in Sandefjord and Hattelco in Arendal. Both companies use AutoStore as a part of their logistics. Film made Hatteland Solutions, Directed/Edited/Photo by Eivind jul Wibe Fiksdal.

Warehouse Integrated Sensor Control

The typical warehouse has over 50% of its floor area, visited for less than 10% of the day. Turret trucks and folks deliver and retrieve pallets generally in less than 3 minutes and return within 30 minutes; that's activity for 10% of the functional day. That's 2 visits per hour and 6 minutes of every hour.

Warehouse LED Lighting by ActiveLED

ActiveLED® High Bay LED lighting fixtures are designed for warehouse or manufacturing environments and offer a 90,000 hour "No Light Loss" warranty.

SIMPLE UPGRADES TO MAKE YOUR WAREHOUSE MORE ECO-FRIENDLY

Adopting greener practices in your warehouse can improve your company's bottom line. There are lots of reasons for businesses to incorporate more environmentally friendly methods. Energy efficient practices can reduce costs, improve employee safety and health and decrease waste. If you want a more eco-friendly business, consider introducing some of the following practices into your warehouse design and management.

ELECTRICAL UPGRADES

Outdated electrical systems waste energy. With a new system, you could potentially reduce your warehouse's electricity consumption. Make sure to hire an electrical contractor that understands how to develop an efficient, streamlined design.

A qualified industrial contractor will be able to improve your systems with a minimum of down time. If you're interested in converting to green energy, your building contractor can advise you about how to proceed.

IMPROVED LIGHTING

In concert with updated electricals, redesigned lighting can make your warehouse more efficient. Well-designed lighting not only cuts your power bills, it can improve the effectiveness of employees. Poorly designed lighting may lead to accidents, contribute to reduced productivity and use excess electricity.

A lighting designer will make a thorough assessment of your warehouse, identifying areas that can be improved. After the analysis, your designer will draw up plans for a new system. Effective light placement and high-efficiency bulbs should be part of the design. The contractor should understand and comply with your area's safety codes. After the new design's in place, you'll have lower power bills, a smaller carbon footprint and a brighter, more comfortable environment.

REDUCE AND REUSE MATERIALS

Most warehouses use a lot of packaging materials. Reducing shipping supplies can help you lower the cost of materials. It can also reduce shipping costs and the resources needed to move products within your facility. Here are some ideas to reduce extra packaging:

Identify areas of waste and make changes to eliminate excess packaging.

Choose biodegradable materials. Using more eco-friendly materials reduces pollution and minimizes your employees' contact with potentially harmful substances.

Reuse materials such as pallets, plastic totes and shipping supplies.

Recycle materials you can't reuse.

Adopting eco-friendly practices in your warehouse doesn't require a complete overhaul of your facility. Relatively small changes and redesigns reap big rewards in energy savings and a reduction in pollution.

Storee's professional electricians can help you convert your warehouse to more efficient and green systems. We've been designing state-of-the-art industrial and commercial solutions for nearly half a century. We can help you make your warehouse more eco-friendly with up-to-date, streamlined electrical and lighting systems.

Warehousing & Distribution

Looking for a specialist to store and distribute your hazardous or non-hazardous goods? Need customised services from a logistics hotspot? Based in the Netherlands, global player Broekman Logistics has over 50 years of experience in warehousing and distribution, freight forwarding, fiscal representation and Value Added Services.

Warehouse health and safety hazards

Toyota SpotMe warehouse safety system

Introducing Toyota Spot Me warehouse safety system - for more information visit www.toyota-forklifts.co.uk

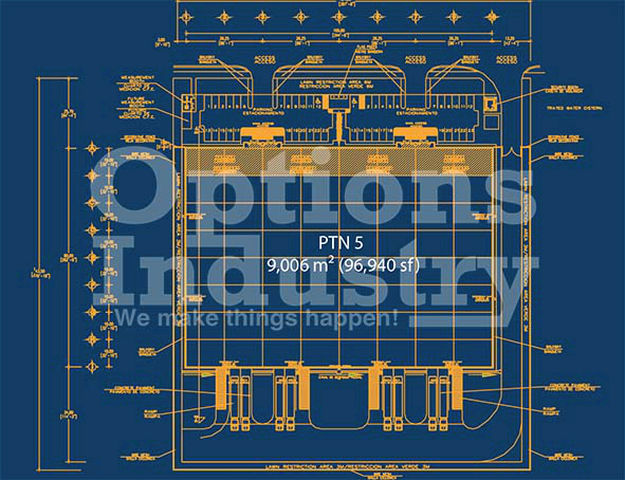

MEXICO CITY WAREHOUSES FOR LEASE AND SALE

H.Essers Video: Warehousing, Transport & Systems

H.Essers is a dedicated logistics provider that offers tailored transportation and logistics solutions throughout Europe. It is now one of the leading companies in Europe in major transport and logistics sectors.

Amazon Prime Air

Dynamic 3PL Logistics Warehousing, Inventory Management, Transportation Management, Kitting.

Dynamic 3PL - Specializing in Warehousing, Inventory Management, Transportation Management, Kitting, Display Building and Packaging provides the full range of warehousing and transportation management services, with a focus on cost-effective and value-added solutions to meet your more complex logistics needs. We use the latest technology to assure orders

The Top 10 Supply Chain Trends for 2016

From this broad economic and technological perspective, Laverty posits 10 specific supply chain and warehousing trends we have seen in 2016:

1) Omnichannel strategies proliferate.

More organizations want to support an omnichannel environment with real-time demand fulfillment and provide a single, unified customer experience across all channels. "Expect to see the trend of more items purchased outside of brick and mortar stores propelled by a strong online showing in Q4," says Laverty. As omnichannel becomes the de facto approach to market, inventory optimization will take on greater importance, as product availability and timely fulfillment become essential across all channels.

2) Big data analytics improve demand planning and inventory optimization.

Big data analytics will drastically improve planning and replenishment, creating lean and balanced supply chains with sophisticated inventory systems. These tools will maximize workflow, increase efficiencies, and directly impact revenue by optimizing warehouse inventory and floor space utilization. "Demand planning and forecasting is an area where many organizations lack tools and process expertise," comments Laverty. Forecasts are based off of snapshots of past requirements, and then people guesstimate how much is needed for the coming year. "More and better data analytics are changing the landscape," says Laverty. "We see people trying new methods and tools as they seek smarter solutions to get the right data to create better forecasts. They will look for additional resources and systems of information."

3) Mobile continues to dominate.

Warehouse management continues to move away from traditional tools to tablets and smartphones. Mobile requirements from solution providers, partners, vendors, and clients are increasing as the expectation that all work functions can and should be completed from smart phones and other mobile connected devices. "Within a warehouse, whatever the function and whatever the role, we have to put money into supporting a total mobile experience for the workers," says Laverty. This includes individual performance metrics and the ability to see roadblocks or interruptions in real time to solve them in real time.

4) Labor looms as a challenge and cost-cutting target.

"In 2016, we see all organizations looking at labor as the primary area where they can reduce costs," says Laverty. "Labor costs will be an even bigger challenge as the minimum wage increases through new regulations." A primary concern will be a shortage of warehouse and transportation labor. Shortages will continue as the labor market tightens, something else likely to drive up hourly wages. "Being able to track productivity and forecast where labor is going to be needed and how it is going to perform is going to be a critical need," predicts Laverty. "Programs that tie compensation to labor production will be a solution that more companies will look to implement." Labor retention will also be a major concern; in states where minimum wage increases are mandated, expect to see advances and investment in warehouse automation. Material handling systems will be prominent in this development.

5) Demands for traceability will be on the rise.

Requirements for traceability continue to be important as FDA and government regulations on food and medicine increase and as stronger pharmaceutical requirements will be enforced in 2016 and beyond. "We see a growing trend of requirements for tracking chain of custody that flows with the product, rather than just what is in your facility," notes Laverty. Traceability will be essential not only where the product is in real time as it moves, but also relating to its pedigree: where it came from, how did it get here, how long has it been in route, was it modified along the way. All that information needs to be passed downstream.

6) Data security requirements become more rigorous.

Organizations will become more demanding of top-of-the-line data security and will begin creating more strategic plans about destroying data and monitoring what they are capturing, since the more they capture, the more liable they are. "It will become very important to be able to offer the highest level of data security and encryption possible," says Laverty. "People want to know what contingency plans are in place for data security and how they are administered." Those storing data within a multi-tenancy community want assurances that their data is never mixed with another client's data.

7) The cloud transition continues.

In 2016, costs will prove to be a huge driver to the cloud for those organizations that are still running legacy applications. The challenge of infrastructure, maintenance, and labor costs will necessitate their transition to the cloud. Four out of five new buyers are looking to the cloud simply because they don't want to deal with the infrastructure, labor, and additional layers of responsibility and risk. "A big trend we see right now is that many organizations are transitioning to the cloud due to an aging workforce," adds Laverty. "A lot of really talented technology professionals are leaving and in most cases these people are irreplaceable. How do you compensate for losing people that you can't replace? You put in a system that doesn't ever need to be replaced."

8) Collaboration is king.

Organizations now expect things to work together and collaborate; full integration of all systems is the goal and there will be lower tolerance for cost and time in realizing this need. This "collaborative orientation" will drive more people toward Platform as a Service (PaaS) offerings, where they have pieces of a platform rather than dealing with systems as separate entities. This shift will require additional understanding of how they all work together.

9) Coping with complexity will be vital.

Perhaps one of the biggest trends of the year will be complexity. The supply chain and warehousing industries are adding more levels of complexity. Taking complex issues, making them easily understandable, and then breaking down that information into packets that are easily consumable will become a major need and driver for creative thinking within the sector. One practical example: instead of making you dig down through a 350-page guidebook, Upp Technology now offers videos, tutorials, audio podcasts, and quick guides in order to break down the complexity of each subject and make it easily understandable for everyone.

10) EDI persists.

Electronic Data Interchange will continue to be an important trend, with more people subscribing. Companies that haven't used a formal process in the past are going to find it harder to exist without using EDI. "In the 3PL and wholesale distribution world, it's obviously a huge trend," says Laverty. "Organizations must adopt EDI to stay compliant with their vendors. We see more partnerships occurring to embed EDI in applications. We also believe that the adoption of AS2 as a communication platform will only increase because it's free."

New vs Used Warehouse Material Breakdown

At Industrial Storage, we love that we can offer both new and used to best fit your individual budget or warehouse needs. When starting the process to find high quality warehouse material, deciding between purchasing new and used material can be a tough choice.

To help make the purchasing decision, we've made a quick list to help you weigh the pros and cons.

1. Price

Unsurprisingly, used storage material is less expensive than new warehouse material, which is one of the biggest deciding factors when looking to purchase material. Be sure to know your budget before starting your search for material as it can help you eliminate many potential businesses. With cheaper options by selecting used material, it is easier to accommodate for large orders or for anyone on a budget.

2. Quality

With new storage material from Industrial Storage, you are guaranteed the highest quality storage material available nationwide. Although we only sell the best quality used warehouse material, nothing can beat the reliability of new storage material. Purchasing new material can be much more expensive but it is more likely to not need repairs or replacement as soon as used material does.

3. Availability

Large quantities of used storage material can be difficult to track down, depending on the location of your business. Although we offer a huge selection of both new and used storage material, special orders of large quantities can be difficult to find other places. Keep in mind how much pallet racking or material you need because availability can vary from manufacturer or distributor.

Simply Pick Faster with Autonomous Robots in the Warehouse.

Our solution gives workers more time on task, minimizing time spent walking around the warehouse. LocusBots work collaboratively and safely alongside your associates. You can easily meet peak period demands and respond to volume increases - simply add more LocusBots.

TORU Robot Does Things Amazon´s Automated Helpers Can´t.

A Dexterous Warehouse Robot Does Things Amazon's Automated Helpers Can'tThe Toru robot can take items off the shelf all by itself, which means less need for human...

Warehouse Management Software Company

3PL Warehouse Management Software Company (WMS)After all the anticipation for Curotec's new Third Party Logistics(3PL) software, Order Manager, the product is out, in use, and living up to the hype!

Another way to make your inventory.

5 Fundamental Practices to Make The Implementation of Warehouse Technology Pay off Big Time.

Make Warehouse Process as Simple, Efficient, and Technologically Driven as Possible

Minimizing the steps in the process is a good way to ensure you have a more rapid movement through the warehouse and the freight process. You can benefit from automated packing and shipping processes, such as the use of a transportation management system, for a more efficient outcome and flow around the warehouse on the outbound side of getting out product to your customer. It will take some operational changes and a look at implementation of technology such as ERP, WMS, and TMS, but it will be well worth the effort in the long run. This is especially important when it comes to storage facilities and storage solutions in general.

Technology is Amazing, But Let's NOT Forget the Common Sense Fundamentals to Maximize the Use of Warehouse Technology

1.-Make sure the Warehouse is Aligned to What the Business Wants: Align the operations of your warehouse with the business goals you set in mind when you decided to implement new processes and warehouse technology. Even if you have pressure coming in from your customer base to speed things up, you should still keep your business objectives in mind as well. Find a good balance of action and strategy to ensure you meet both ends of the spectrum for optimum results.2.-Training: Employees must be trained on procedures, including interaction with the warehouse technology you are implementing such WMS, ERP, or TMS . The excellent manager spends quality time with each team member to coach and encourage him or her. The WMS provides individual performance data to inform the manager as to who needs what specific training. The manager needs to then continually improve using this data.3.-Employee Motivation: Employee motivation can begin as simply as posting charts of comparative performance to encourage competition. After some data have been collected from the WMS, standards should be established for each warehouse task. Employees who exceed standards can be rewarded informally with perks or specific prizes. Ultimately, a formal gain sharing program can entice an appreciable increase in productivity. Productivity increases of 30% have been reported.4.-Physical Plant: An excellent warehouse includes adequate dock capacity, ample staging areas, appropriate storage (pallet rack, shelving, flow rack etc.), and suitable equipment (carts, pallet jacks, fork lifts, order picking trucks, etc.). In general, a single level warehouse is preferable, but conveyors and other mechanization can make a multi-level facility nearly as efficient. The excellent warehouse manager plays a proactive role in planning physical improvements.

5.-Automation technology: Of course, fundamentals are exactly what automation is all about. It takes manual tasks, that when executed exactly the same with best practices in mind, can do well, and uses technology to always have the process repeat and scale as expected. This includes vertical and horizontal carousels, conveyors, automatic stacker cranes, automatic pallet wrappers and many other mechanization. The forward thinking warehouse manager will periodically evaluate potential automation projects. The guiding principle here is whether any proposed automation investment in the various warehouse technology available, provides an acceptable financial return. Picking rates using a well engineered bank of horizontal carousels can be three to four times those possible from fixed shelving, transportation costs and resources are now lowered due to less errors, more control, and increased customer happiness....and finally, the accounting department, with great visibility into these processes, will love the new look of a more profitable bottom line.

The Next-Generation WMS with Voice Picking.

A fundamental shift is underway as thought leaders review their existing distribution center processes: Many now call the voice-enabled warehouse the next generation in distribution center and warehouse material-handling management. In the voice-enabled warehouse, there are fewer alphanumeric keyboards, and scanning provides secondary worker enablement. The business argument for voice-enabling technology is simple: Speech for the distribution center worker quantitatively provides measurable business value.

New Warehouse Construction Timelapse.

November 23 , 2016

Easy WMS Warehouse Management Software

November 22, 2016

What is Easy WMS?

Easy WMS is a Warehouse Management Software (WMS) that offers an extensive range of functionalities that allow to work efficiently in each of the areas and processes of the warehouse. It is a powerful, robust, versatile and flexible software that simplifies and optimizes the management of your warehouse. Complex or simple, large or small, automatic or manual, whatever your business or sector, Easy WMS has a solution for all types of warehouses.

Why an SGA can make your warehouse profitable?

With the installation of a Warehouse Management Software (WMS) you can optimize all the movements, processes and operations within your warehouse. This will result in cost savings and an improvement in service quality.

With Easy WMS you can control:

• Receipts of merchandise

• All storage tasks

• The process of preparation of orders and expedition.

What you will get with Easy WMS?

Here are some of the benefits you will gain from implementing the Easy WMS Warehouse Management Software:

Up to 40%

Of improvement in the use of space.

Up to 30%

Reduction in maintenance items.

Up to 30%

Productivity improvement in order preparation.

Up to 25%

Reduction in returns to customers.

Up to 30%

Reduction of handling operations.

Up to 40%

Reduction of stock costs.

Up to 99%

Of error elimination.

Plus:

• Traceability

• Real-time permanent inventory

Security Projects for logistics centers and transport companies.

November 15, 2016

Security systems for the interior and exterior of the ship. Mobile protection

systems for vehicles.

Videocontrol logistic

Closed Circuit Television systems to cover areas of loading and unloading, access, areas of risk material. Decentralized systems for multi-station video surveillance management.

Alarms Intrusion

Special intrusion protection systems for interior of ship, and perimetral systems for external detection, for early detection.

Access control

Access control systems for entry of vehicles authorized by license plate, tag, hands-free, remote opening, etc.,

FIRE PROTECTION

November 11, 2016

Foams

Foams used in fire suppression consist of a mass of gas filled bubbles, formed from aqueous solutions of foaming agents of various formulations. To generate the foam, the water flow passes through different equipment where it is properly mixed with the substance that generates the foam.

They are used primarily and effectively to extinguish fires in flammable and combustible liquids because they float over them and form a continuous layer of aqueous material that displaces air, cools and prevents the escape of vapors. The foams extinguish by drowning the fire, preventing the passage of vapors, separating the flames from the surface of the fuel and cooling the surface of the container and fuel.

The main characteristics of the foams are:

• • Expansion

• • Decanting

• • Resistance to resignation

• • Extinguishing rate

• • Compatibility with chemical powders

• • Viscosity

• • Surface tension

There are three types of foams depending on their "expansion". The expansion is the ratio of the volume of foam formed to the volume of solution used.

• Low expansion foam (less than 20).

• Half expansion foam (between 20 and 200).

• High expansion foam (between 200 and 2000).

Fields of application: Manufacturing and repair plants, storage tanks, refineries, airports, laboratories, chemical warehouses, tanks with fixed roof, tanks with floating roof, loaders, hangars, LP gas tanks, etc.

We have the widest range of foam-based fire protection solutions. Ideal for protection in the manufacture, storage and transport of large volumes of dangerous chemicals, flammable liquids, ensuring the best cost-benefit ratio for the protection of this type of risks.

Some typical applications for these systems are:

• Chemical industries, processing and storage areas

• Storage tanks for combustible liquids aeronautics, airports, (landing and take-off area)

• Installations in petrochemicals

• Off-shore platforms

• Warehouses.

FIRE PROTECTION

November 11, 2016

The Firetrace Indirect Fire Extinguishing System uses the tube as a fire detector and system activation device, not as a discharge path.

Once the pipe detects the fire, then it breaks resulting in a drop in pressure causing the indirect valve to activate.

Then the fire suppression system comes into action, the extinguishing agent is discharged from the cylinder through diffusion nozzles, flooding the area into a mixture of effective fire extinguishing chemicals, suppressing the fire quickly and completely.

This system is typically used in larger areas requiring a high volume of extinguishing agents, to effectively suppress fire. Multiple diffuser nozzles can be added to meet specific application requirements.

¿What can we do to regulate the temperature and input of heat in an industrial ship?

October 29, 2016

We currently have several systems of insulation from sunlight, either by applying a coating to the roof or using another type of materials. Today there are other options such as one who gives us the Somfy company, since within its automation systems it presents FTS (Fabric Tension System), this is a system designed by Somfy, solving the sunscreen at any entrance of light, because it is adaptable to various dimensions and almost any orientation. To the be retractable and discreet retains the cleaning of the design architectural, exists in several configurations that meet in geometries complex, are adapted to any design architectural; domes, skylights, double height and facades with slope, etc.

Advantages

-Minimal maintenance.

-Operating independent or coupled to driver overall.

-Performance coupled with sensors.

-Points LEED implementation.

-Included design and engineering service.

Certification

SOMFY contributes up to with 22 points in projects for certification LEED, in the following fields:

-Materials and resources.

-Sustainable sites.

-Energy and atmosphere.

-Quality of environment inside.

-Innovation and design

Above you can see an image that show us how this system works.

¿Do you know the advantage of using polycarbonate roofs?

October 25, 2016

The polycarbonate roofs are made up of plates of a material hard, tough, lightweight, durable, easy to mold and dye in hundreds of colors plastic, which already if delivery many possibilities as we can manipulate it for different environments . When cover surfaces where we want keep lighting, this material is suitable for its properties and innumerable advantages. Polycarbonate is commonly used when a material through which it can look, and very resistant needed. There are four types of polycarbonates for installation of roofing: smooth compact polycarbonate corrugated plates, polycarbonate plates 5V and fretwork and cellular polycarbonate plates. The polycarbonate roofing sheets can be installed on different types of structure: wood, metal, aluminum, etc. Installation is not complicated, but requires attention to some details and care. Some of the benefits offered polycarbonate roofs are:

It is a translucent material: being a plastic, allows normal passage of light, which is a benefit for constructions or ceilings where constant lighting is a critical variable.

It is moldable: depending on the type of project that required, polycarbonate can be cut, stretched or bent to accommodate the needs of the work. Thus, the polycarbonate allows setting ceilings in many different shapes and designs.

It is very resistant: polycarbonate is capable of withstanding heavy blows or falling objects without cracking or damage, unlike glass which is much more fragile. These polycarbonate resistance makes ideal for the manufacture of roofing material.

It is durable: it is well known that plastics have the property to be preserved for a long time, saving on maintenance costs and enhancing their property. This durability is suitable installing polycarbonate roofs outdoors.

It provides thermal insulation: this plastic material is very good to avoid heat loss, why is widely used in works such as greenhouses or swimming pools. As roof, polycarbonate is a material that provides adequate insulation in a wide variety of facilities and works.

It is lightweight: thanks to its low weight, the polycarbonate does not require that construction be too complex to be sustained structures, which tends to reduce the final costs of the project. Thus, polycarbonate roofing installation is faster and easier because of the lightness of this material.

Metal Covers

October 5, 2016

The metal covers are the trickiest part in any industrial building construction, design requires reliability and durability, because otherwise you run the risk of leaks, the roof is due, among others.

The theme of the stamps on the covers is important because if not done properly result in leaks that can cause severe damage to what is stored or safeguards in industrial roofing. We therefore recommend contacting experts and not only teachers who offer inexpensive material without actually making a calculation or analysis of the project.

Another issue to look at metal covers is that they must withstand very large and perfectly lighting system or cooling loads.

Our roofing systems SSR type (Standing Seam Roof) plant with lateral grooved union splined to 180 °. Required for attachment of clips which is hidden to make the lateral attachment does not require drilling parts for fixing. Available in widths of 45.7cm (18 "), 61 cm (24"), effective width and with a camber of 7.6cm. In any option includes the lateral sealant applied in plant also has fully developed accessories to ensure the impermeability of the cover. It can be supplemented with insulating materials. It allows to be installed on low slope roofs (up to 2%).

Available in painted sheet Galvakolor either traditional or Galval galvanized coating. Dimensions according to the needs of each project. Available in sizes 22 and 24. System covered with more certificates against wind suction (FM).

Ecological and Efficient Cooling.

September 25, 2016

Exchanger Heat and Mass Delphi (Heat and Mass Exchanger, HMX, for short) is a "motor" or cooler component behind the air conditioning high efficiency that uses water as fuel and is able to cool homes, buildings offices and industrial buildings at a cost much lower than traditional cooling systems without generating greenhouse gas emissions operation.

The company Delphi Corporation is responsible for developing and bringing to market of air conditioning and refrigeration product that offers a cooling system responsible environmental, with superior performance and a much lower cost.

The "Coolerado" of residential products, series sold by Coolerado Corporation subsidiary Cooler Air Systems LLC (CAS), is the first product line developed around this innovative technology. Thanks to its efficiency, "Coolerado Cooler" was recognized in 2004 by the program 100 Awards R & D Magazine (R & D) as one of the most technologically significant products introduced into the world market.

Thus Delphi started producing at the stage of manufacturing this product in 2006, and the response has been on the market has been quite favorable, as they have around 100 residential and commercial facilities, as well as about 12 industrial.

This system works through a thermodynamic cycle developed by the Russian scientist, Dr. Maisotsenko, who discovered this new process to cool air.

The HMX advantage from a thermodynamic cycle called Maisotsenko Cycle or Cycle-M, this cycle uses the infinite reservoir of atmospheric energy in producing a considerable cooling with excellent efficiency. So the HMX produces cold air by Cycle-M using water as fuel without adding a single drop of moisture.

Therefore, the more heat exists outside the HMX works best, because with the outside temperature cooling capacity and the rate of energy efficiency of the implementation of this component, a feature that drastically reduces consumption increases energy during peak periods when energy is more expensive.

PLANTAS SUSTENTABLES DESDE SU DISEÑO

August 26, 2016

No basta con tener un sistema de tratamiento de agua o de generación de energía renovable; la sustentabilidad considera un crecimiento basado en tres pilares fundamentales: económicos, ambientales y sociales.

Construir una nave sustentable cuesta 12% más que un edificio convencional, pero los ahorros económicos y en beneficio del medio ambiente garantizan un retorno de inversión anual del 25% al 40% a partir del tercer año.

EXCELENTE IDEA HACER UNA NAVE SUSTENTABLE!

¿QUE OPINAS SOBRE EL TIEMPO DE RETORNO DE INVERSIÓN?

¿Sabes cuales son las características de un almacén perfecto?

January 5, 2016

Debe estar convenientemente ubicado: cerca de carreteras, ferrocarriles, puertos aéreos, marítimos, etc. Esto facilitará la carga y descarga de los bienes y mercancías.

Hay que contar con los aparatos mecánicos y tecnológicos necesarios para levantar, cargar y descargar mercancías.

Debe ser lo suficientemente espaciosa.

Deben contar con las condiciones necesarias para mantener los bienes en perfectas condiciones. Debe tener las condiciones perfectas para todo tipo de bienes, por lo que debe protegerlos siempre de la luz solar, el polvo, la lluvia, la humedad y las plagas.

Debe contar con suficiente espacio de estacionamiento para facilitar la carga y descarga de mercancías de una forma rápida, sencilla y efectiva.

Deben establecerse las medidas de seguridad necesarias, tanto con sistemas de videovigilancia con guardias de seguridad para asegurar que las mercancías están siempre a buen recaudo. Estas medidas de seguridad deben ser estrictas y estar activadas 24 horas al día. Asimismo, debe contar con una instalación moderna y probada contra incendios.

Algunos puntos claves si quieres comprar o rentar una nave industrial.

August 5, 2016

Uso de la nave

En primer lugar, tenemos que valorar si queremos destinar la nave a un uso industrial o comercial. Aunque este último es menos frecuente, hay muchas naves industriales que se destinan total o parcialmente a este uso, como los outlets o las empresas industriales con showrooms y venta al detalle.Ubicación

La ubicación es fundamental. En primer lugar, debemos tener en cuenta las infraestructuras que hay en la zona, tanto en relación a comunicaciones (vías de comunicación, distancia a puertos o aeropuertos u otras infraestructuras relevantes para la empresa) como servicios complementarios de la zona.Superficie

Cuando hablamos de superficie no nos referimos solo al tamaño de la nave en sí, es decir, a los metros cuadrados útiles o totales. Este elemento es importante, pero también debemos tener en cuenta la alturade la nave, la distribución de los espacios que necesitamos, la anchura de determinados lugares como pasadizos o puertas de acceso...Acondicionamiento

Valorar los acondicionamientos de una nave industrial requiere ser metódico y detallista cuando requerimos información. Por ejemplo, no solo tenemos que preguntar si tiene los suministros básicos de agua, luz o gas, sino qué potencia hay contratada o podemos llegar a contratar con las condiciones actuales de la nave, estado de las instalaciones, y si hay desagües... Los diferentes elementos estarán definidos por nuestra actividad industrial, lo más recomendable es hacer una lista de requerimientos básicos y opcionales que necesitamos en la nave para no dejarnos nada.

Tipos de naves industriales.

August 5, 2016

Los tipos de naves industriales se clasifican de acuerdo a los materiales utilizados en la construcción de su estructura:Naves con estructuras de acero

Las naves con estructuras metálicas tienen la ventaja de que permiten una construcción rápida y al mismo tiempo obtener espacios iluminados más grandes, sin la necesidad de montar pilares dentro del inmueble.

Naves de hormigón prefabricado

Las naves de hormigón prefabricado son fáciles y rápidas de armar, pues prácticamente sólo se tiene que conectar las piezas, sin embargo en cuanto a iluminación se encuentran en desventaja, pues no llegan a ser muy altas.

Naves de hormigón "in situ"

Las naves de hormigón "in situ", aunque son las más económicas, estas construcciones industriales están por desaparecer ya que los tiempos de ejecución son largos y presentan carencias en la iluminación. Su única ventaja es que la nave se puede realizar en forma de edificio, pudiendo tener varias subestructuras dentro de la planta.

Naves mixtas

Las naves mixtas tienen combinan estructuras de acero y hormigón para realizar geometrías especiales en el inmueble. Una de las ventajas que tiene sobre las construcciones normales de estructuras de hormigón y acero, es el ahorro en costes de materiales, pues durante el montaje se pueden realizar procesos conocidos como pretensados y postensado, que consisten en generar esfuerzos permanentes en la estructura de manera intencionada para mejorar su desempeño.

¿Qué tipo de nave industrial tienes?

¿Ya conoces el método de construcción TILT UP?

August 2, 2016

El método Tilt-up es un sistema de construcción de muros delgados de concreto hechos en obra que se dividen en secciones, llamados paneles. Estos son colados directamente sobre la losa del piso de la estructura o sobre una plataforma de trabajo para que una vez alcanzada su resistencia de proyecto sean izados con una grúa y colocados sobre los cimientos, formándose así la fachada de la Nave Industrial. Es un orgullo saber que ATISA Industrial es pionero en implementar el método del Tilt-up en la construcción de Naves Industriales en México.

A continuación nos gustaría mencionar alguna de las ventajas que tiene el método de construcción Tilt-up:

1. Menor costo en la construcción. Cuando existe la maquinaria adecuada y el personal calificado, el sistema Tilt-up resulta más económico que los métodos tradicionales. Los muros Tilt-up ofrecen un excelente producto en términos de construcción, operación e inversión. Por su agilidad de construcción, se perciben grandes ahorros en mano de obra.

2. Despliegue rápido con proceso rápido. Generalmente la construcción con Tilt-up dura 30% menos que un edificio similar hecho de bloque o densglass. También los sistemas de ingeniería y productividad en serie permiten ahorrar en tiempo y mano de obra.

3. Aspecto profesional para las visitas de clientes. Desde el punto de vista arquitectónico las Naves Industriales con muros Tilt-up son más estéticas que las que conciben de lámina y/o mampostería. Por lo que Atisa Industrial diseña cada proyecto, salvo por indicación del cliente, de muro de Tilt-up y satisface todas las especificaciones, necesidades y gustos del cliente.

4. Extremadamente versátil para futura expansión. Los paneles Tilt-up son fáciles de modificar para acomodar nuevas aberturas o ampliaciones de Naves Industriales. Las columnas suelen ser de pieza de acero por lo que se mueven con mucha facilidad y en varias ocasiones se pueden mover paneles enteros o dejando una cara del edificio con láminas para su ágil remoción y reemplazamiento por un muro de concreto.

5. Estupenda acústica y aislamiento térmico. Utilizando el método de Tilt-up podemos lograr mejores propiedades de aislamiento término y acústico, así como una mayor resistencia al fuego, sobre todo a partir del perímetro. Los muros de concreto, que están reforzados con acero, ofrecen una barrera natural a las varias fuerzas que pudieran incomodar y hasta dañar, como son los ruidos fuertes, cambios bruscos de temperatura, así como incendios.

3 tendencias que moveran al sector inmobilirario en el 2016

19 july 2016

A pesar de dificultades como la apreciación del dólar y el clima de inseguridad en el país, el sector inmobiliario salvará este año y seguirá creciendo, gracias a tres factores. Aquí te contamos. La depreciación del peso frente al dólar y el clima de inseguridad en varias regiones del país serán los principales retos que enfrentará el sector inmobiliario en 2016. Sin embargo, los jugadores en el mercado esperan que los crecimientos del sector se mantengan a lo largo de los próximos 12 meses. A continuación te presentamos tres tendencias que moverán al sector inmobiliario durante 2016, de acuerdo con la perspectiva de los jugadores en el mercado.

1. Desarrollo automotriz, imán de inversión inmobiliaria.- La industria automotriz ha sido una de las más dinámicas en México. La instalación de nuevos complejos automotrices de firmas como Honda, Nissan-Renault, Mazda, BMW, Mercedes-Benz y Audi tiene el potencial de detonar inversiones en el sector inmobiliario. Los lugares relacionados con la industria automotriz se verán beneficiados por las inversiones inmobiliarias que se realicen, mientras que los espacios relacionados con energía aún no logran atraer inversiones, comenta Pedro Azcué, de JLL.

"El desarrollo del sector va a estar muy en línea con el crecimiento de la economía, entonces seguiremos viendo crecimientos en el piso de ventas y una estabilidad en las ocupaciones", explica el analista de Ve por Más.

Nuevo León, Jalisco, Querétaro, Guanajuato y San Luis Potosí son otros estados que muestran una dinámica creciente en el desarrollo inmobiliario, agrega Marco Medina.Asimismo, otros sectores podrían incentivar el crecimiento inmobiliario. Se requieren centros logísticos conforme llegan nuevas empresas e incluso el comercio electrónico también crece con la llegada de Amazon, dice el analista, quien observa espacio para nuevos proyectos en Monterrey y Guadalajara."Yo creo que aún hay confianza por parte de los inversionistas en cuanto a nuevas inversiones", apunta Medina.

2. Uso mixto, el desarrollo preferido.- La falta de espacios ha traído consigo un avance del desarrollo de proyectos de uso mixto en el sector inmobiliario. Hospitales, centros comerciales, hoteles y oficinas son algunos de los usos que caben en estas construcciones.El dinamismo que ha tenido la Ciudad de México ha propiciado el desarrollo de los usos mixtos: "Vivimos en una ciudad donde la movilidad es bastante complicada, donde los espacios públicos no son los que quisiéramos tener y nos vemos forzados a permanecer en un área de influencia. Los desarrollos de uso mixto nos brindan esa oportunidad de tener todas las ofertas en un lugar muy conveniente y seguro", afirma Elías Mizrahi, director de Relación con Inversionistas de Fibra Danhos. Monterrey, Guadalajara y la capital del país son territorios fértiles para erigir este tipo de proyectos, aunque la zona del Bajío también podría ofrecer oportunidades en el largo plazo.

"Nosotros creemos que, sin duda, la zona metropolitana de la Ciudad de México sigue siendo el mercado inmobiliario más maduro del país y probablemente lo siga siendo por mucho tiempo", dice el directivo de Fibra Danhos.

3. Más Fibra para el mercado .- Las Fibras son una tendencia que seguirá impulsando al sector inmobiliario en 2016. "El panorama general para las Fibras se ve bien para el año que entra. Hay muchas oportunidades de crecimiento", dice el director de Relación con Inversionistas de Fibra Danhos. El año pasado, Luis Méndez Trillo, presidente de Coldwell Banker Commercial en México, aseguraba que cerca de 10 nuevas Fibras enfocadas a bienes comerciales podrían sumarse a los 11 jugadores que actualmente cotizan en la Bolsa Mexicana de Valores (BMV).

"Hay espacio para que se incorporen hasta una decena de Fibras generales", dijo Méndez Trillo en la inauguración de sus nuevas oficinas corporativas en el poniente de la Ciudad de México. "Llegaremos a un punto en que la curva se estabilice", dice José Elizalde.

Por lo pronto, empresas como Coldwell Banker observan un año prometedor para el desarrollo de las Fibras y de todo el mercado inmobiliario. El 2015 trajo un crecimiento de 100% en venta de franquicias para Coldwell Banker, y cerraron con 69 oficinas, de las cuales 11 son nuevas y para 2016 esperan superar las 80. "Vemos un 2016 prometedor para la parte residencial y comercial", explica Elizalde.

En la actualidad existen desarrollos residenciales de tipo medio que presentan un costo por metro cuadrado que se vende a partir de 23,000 a 30,000 pesos con buenos servicios en zonas como Lomas Verdes. El mercado mundial de capitales inmobiliarios se estima en 245,000 millones de dólares (mdd) anuales, mientras que en México apenas alcanza 5,000 mdd al año. "Somos una parte muy pequeña de las operaciones mundiales por la escasez de terrenos", dice el CEO de JLL.

Sin embargo, no considera que las Fibras vayan a ser los principales desarrolladores de usos mixtos, ya que aún falta que el mercado de inversionistas sea más maduro en estos instrumentos, pero sí ve como jugadores centrales del negocio a las empresas inmobiliarias.

A pesar de que 2015 no fue el mejor año de las Fibras, las inversiones continuarán este año y el sector inmobiliario quiere poner los cimientos en un crecimiento sostenido hacia 2020.

¿Por qué el Brexit afecta tanto a México?

19 july 2016

Después de que se hizo pública la decisión del Reino Unido de abandonar la Unión Europea, la mayoría de los mercados financieros y de divisas comenzaron a reaccionar de manera negativa, y México no fue la excepción.

El saldo en los mercado globales de divisas fue el siguiente: respecto al dólar estadounidense el dólar canadiense cayó 1.5 por ciento, el euro menos 2.2 por ciento, la libra esterlina menos 7.9 por ciento, el yen japonés subió 3.5 por ciento, el peso argentino retrocedió 3.6por ciento, el real brasileño menos 1.3 por ciento, el peso chileno menos 1.5 por ciento, el yuan chino menos 0.7 por ciento, el peso colombiano menos 1.5 por ciento y el peso mexicano menos 2.9 por ciento. Ante estos datos, surge obligadamente la pregunta ¿Por qué a México le afecta más el Brexit en su tipo de cambio que a otras naciones?

Uno pudiera pensar que es por el 'enorme' volumen comercial entre nuestro país y el Reino Unido, pero la respuesta es negativa. En 2015 México le exportó a dicha nación mercancías por 1.967 miles de millones de dólares (mmdd), cantidad que representó apenas 0.5 por ciento del total de las ventas al exterior de nuestro país. En los primeros cuatro meses de 2016 las exportaciones de México a Reino Unido suman 1.106 mmdd, lo que representa 1.0 por ciento del total de exportaciones de nuestro país.

Respecto a las importaciones de México provenientes del Reino Unido, vemos un volumen similar. En 2015 nuestro país realizó importaciones provenientes de dicha nación por 2.344 mmdd, cifra que representó 0.6 por ciento del total. En los cuatro primeros meses de 2016 las importaciones de México originarias de Reino Unido suman apenas 0.672 mmdd, lo que representa 0.6 por ciento del total de importaciones hechas por México en el periodo.

¿Quién gana o quien pierde más del Brexit en términos de comercio exterior? Pues de entre México y Reino Unido parece que este último es el que pierde más ya que en 2012 México registró un superávit comercial bilateral de 211.8 millones de dólares (mdd), en 2013 tuvimos un déficit de 1.070.3 mmdd, en 2014 registramos un déficit de 707.7 mdd, en 2015 tuvimos otra vez un saldo negativo de 377.2 mmdd y en los primeros cuatro meses de 2016 tenemos un superávit de 433.4 mdd. De esta manera, en el acumulado de 2012 a la fecha, México tiene un déficit comercial con Reino Unido de 1.510 mmdd. Aunque cabe hacer énfasis en que el volumen de comercio entre México y Reino Unido es poco significativo.

¿Entonces, por qué tanto ruido en México respecto al Brexit si los intercambios comerciales son tan bajos? ¿Por qué nos afecta tanto?

¿Por qué se dice que el dólar puede llegar arriba de 20 pesos en los próximos días (de hecho ya el dólar alcanzó 19.3472 pesos por dólar en su cotización interbancaria el viernes 24 a la 1.00 am)?

Parte de la razón de este comportamiento es la enorme cantidad de capitales extranjeros que se encuentran invertidos en México en instrumentos de deuda de corto plazo y en acciones que cotizan en la Bolsa Mexicana de Valores. De acuerdo con cifras del Banco de México, al 31 diciembre de 2015 la tenencia de valores gubernamentales por parte de residentes en el extranjero era de 2.125 billones de pesos y al 15 de junio dicha cantidad ascendía a 1.930 billones, lo que implica una disminución de 9.2 por ciento en casi seis meses, y además significa que los extranjeros aún tienen en México unos 101.921 miles de millones de dólares en Cetes al tipo de cambio actual. De esta manera vemos que la tenencia de valores gubernamentales en manos de extranjeros representa 57.5 por ciento del total de nuestras reservas internacionales.

A manera de conclusión, lo que podemos señalar es que México seguirá en la montaña rusa de los mercados financieros, con efectos mucho más severos que los que sufrirán otras naciones, y esto será así mientras sigamos siendo un país dependiente de la inversión extranjera de cartera. Esta situación no se resolverá en el corto plazo, por lo que tendremos mucha volatilidad en los próximos meses, pero lo que sí se puede hacer es comenzar a trabajar en un plan serio que busque convertir a México en una potencia exportadora. Tenemos la planta productiva para hacerlo, el talento y la capacidad, lo que falta son apoyos y compromiso por parte de los empresarios que desconocen de la materia.

Reduce costos en tu nave industrial utilizando luz natural

January 5, 2016

El uso continuo del equipo de iluminación representa una ventaja al mantener la visibilidad dentro de las bodegas y naves industriales. Por otro lado, también se produce un aumento en el gasto de energía eléctrica con sus respectivos costos monetarios, y se acelera su desgaste, lo que provocará que los equipos deban ser continuamente cambiados o reparados.

Luz natural Para reducir tanto los costos por consumo eléctrico como el desgaste del equipo de iluminación, vale la pena alternar dicho equipo con el aprovechamiento de la luz natural.Si se utiliza un laminado que permita el paso de la luz solar se puede dejar de utilizar una parte del equipo de iluminación, lo que representa un ahorro de energía y la reducción de desgaste del equipo.No obstante, el laminado elegido debe poseer ciertas propiedades, tales como un alto nivel de transmisión de luz y resistencia a la intemperie. Una opción que se adecua a estas necesidades es el uso de Láminas POLIACRYL G5.

Estos productos cuentan con una capa protectora de Gel Coat que no se separa de la resina y le brinda superior resistencia a la intemperie, prolongando así su durabilidad, además de ofrecer mayor continuidad en la transmisión de luz y apariencia más agradable. Pueden ser fabricados con características adicionales que lo hagan retardante a la flama, auto extinguible y de baja densidad de humos (formulación especial).

VENTAJAS DEL POLIACRYL G 5

Las principales ventajas que ofrecen estas láminas son:

- Excelente transmisión de luz

- Resistencia al impacto y a la intemperie

- Excelente durabilidad

- Mayor resistencia química

- Evita la acumulación de polvo

Las láminas POLIACRYL G5 tienen aplicaciones en:

- Naves industriales

- Bodegas

- Invernaderos

- Centros comerciales.